Description

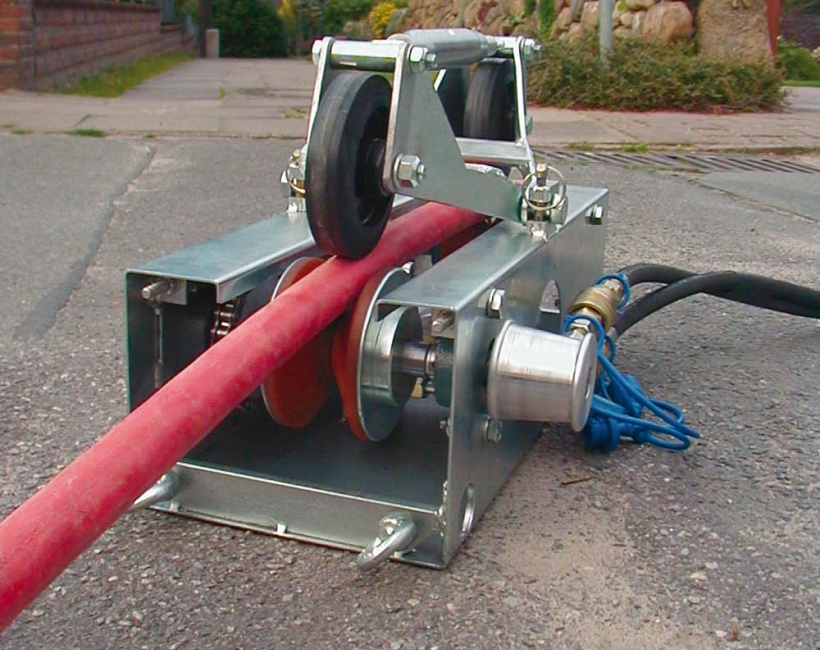

Cable pusher BKS 400

Whether in power stations, industrial buildings or shipbuilding industry, there is only a very confined space for cable laying. The BKS 400 is the perfect tool for these conditions:

• lightweight – only 35kg

• compact – discharging height= 210mm

• versatile – for Ø 11 – 70mm + additional capstan

• high capability – pulling-/pushing power = 400dN

The BAGELA cable and pipe pushing unit BKS 400 is designed for working sites with confined space, and is to be used also within buildings, power plants or on ships. It can be positioned directly into the cable tray because of the low weight and dimensions. The single capstan can be used for pulling in cables or pipes; the pushing device is also able to push or to pull in glass fibre rods with a diameter starting from 11mm.

Function:

The cable passes over two pairs of propelled pulleys. Two counter pulleys press the cable into the grooves of the two driving pulleys. The tapered pulleys consist of a special high elastic and wear resistant rubber material, thus ensuring adequate friction.

The hydraulic power pack is connected with the pusher BKS 400 by two hydraulic hoses; the operation can be easy managed from the ground, also if the pusher is fixed in a tray.

The hydraulic drive of the BKS 400 can be operated by a separate power pack or by another machine like an excavator, if the below listed parameters can be provided. The connecting hoses between the BKS 400 and the power pack are equipped with a flow divider, which guarantees the infinitely variable adjusting of speed.

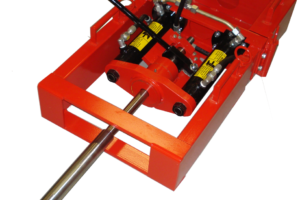

Cable pusher BKS 800

Have you ever been faced with the task of pulling cable along meandering courses, through street under crossings or in narrow ducts? If so, you will know how soon the stress limit of the cable being pulled is reached and how soon you will have to fit a connection piece. In order to avoid premature cable cutting and fitting of connection pieces, it is advisable to use a Bagela Cable Pusher in front of a bend, which will reduce cable stress and allow longer cable lengths to be pulled.

Each use of the Cable Pusher BKS 800 will save the cost of fitting one connection piece. No extra time will be squandered for:

- cutting the cable

- moving the cable drum

- excavating a connection pit

- barring of the connection pit

- refilling the connection pit

Function:

The cable passes over two pairs of tapered pulleys, which are driven by electric or hydraulic motor. Two counter pulleys press the cable into the grooves of the two driving pulleys, thus ensuring adequate friction. For effective power transmission the tapered driving pulleys are consisting of a special, highly elastic, tough and wear-resistant rubber material with a high coefficient of friction.

The gap between the tapered pulleys can be varied, so that cable and tubes of 30 to 180 mm in diameter and three single lead 20 kV cables in one strand can be pushed. After the cable has been laid in place, the press-on unit can be removed and the cable taken out and put aside. As the machine is extremely low (340 mm), there will be no unwanted bends in the cable after pushing. Owing to its compact design the cable pusher may be used in any cable trench or pit.

The cable pusher is driven by an electric motor. By means of appropriate power distributors, several cable pushers may be operated in parallel. Upon request, the cable pusher will be supplied with hydraulic motor to be connected to a hydraulic power pack or the hydraulic system of a mini-excavator.

Cable Pusher BKS 800 used for laying 110 kV cable in an industrial site. Where the passage is free, cable pulling may be continued by means of a cable-pulling winch, which draws the cable direct on to the cable holding shelves.